Meteorite House – a study in the insulation and surface treatment of CLT structures

Meteorite, designed by Ateljé Sotamaa, was the people’s choice winner of the 2020 Puupalkinto (Wood Award) and has gained fame across Finland and internationally. It also won the North Karelia Provincial Construction Project Award in spring 2021 and was part of a virtual display at the Venice Architecture Biennale. The developer and designers were all enthusiastic to experiment with new solutions in CLT construction, which were then studied by the Karelia University of Applied Sciences. What was learned in the project from a civil engineering perspective and where might the new information lead?

Text: Ville Mertanen | Photographs: Karelia-ammattikorkeakoulu, Tuukka Koski, Kivi Sotamaa

Read the article in Finnish: Meteoriitti-talossa tutkittiin CLT-rakenteiden eristävyyttä ja pintakäsittelyä

The designing of the Meteorite House, situated in Kontiolahti, began in summer 2019. The project aimed to test what new forms and solutions digital manufacturing practices could bring to wood construction. CLT Finland Oy was selected as the CLT element supplier and Lahden puurakentajat Oy as the contractor. Besides experimenting with new shapes and structures, the project wanted to study CLT structure thermal insulation and vegetable oil-based surface treatments for exteriors. A collaborative research agreement was signed with the Department of Wood Construction at the Karelia University of Applied Sciences, and the developer and CLT Finland Oy took an active part in the study.

Structure: interiors, intermediate spaces, and exteriors

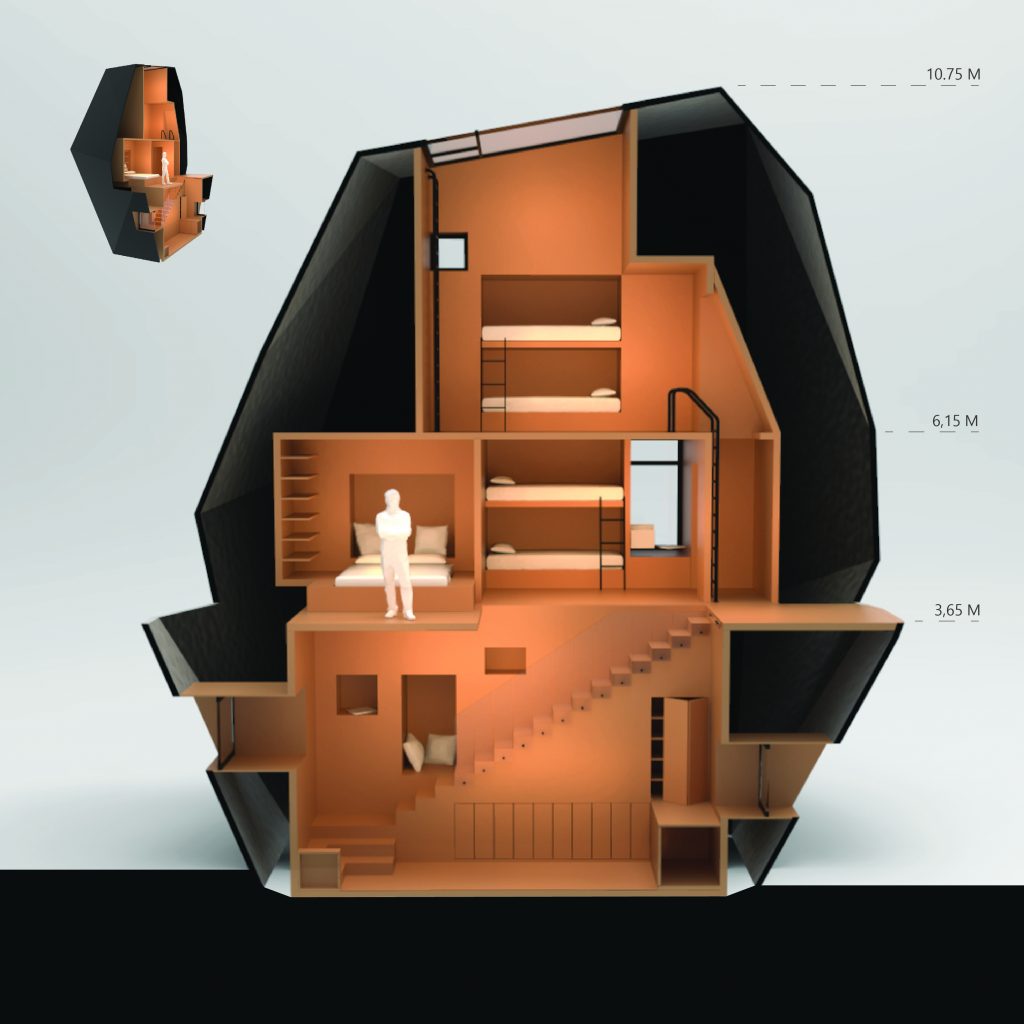

The building consists of three box-like interiors created by placing CLT structures one on top of another. The exterior is a versatile CLT structure cladding. The building technical services run through air space between the internal and external shells. The building does not have an actual insulation layer. Rather, the thermal insulation is based on wood’s natural insulation and the air space in between.

Airspace insulation capacity in CLT structures

In terms of physics, heat is transferred in buildings in three different ways: conduction, radiation, and convection. The sun’s short-wave radiation warms the building exterior. This thermal energy is then conducted through the CLT material by means of vibrations. Of the three transfer methods, convection has the most significant effect on insulation.

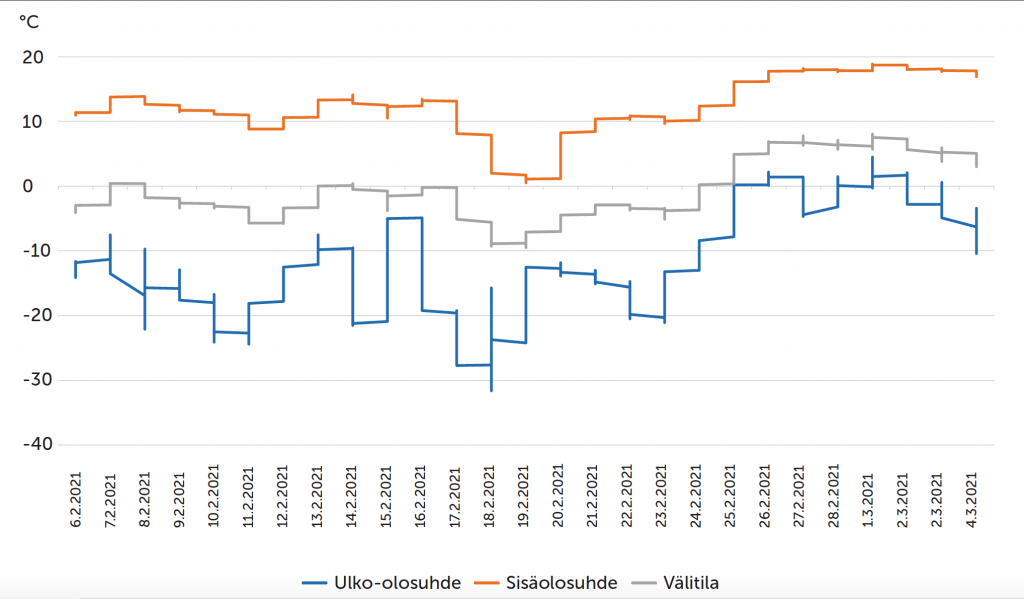

When Meteorite was designed, the presumption was that the air in the intermediate space would act as an insulator between the exterior and interior. However, it was unclear how much convection would occur in the intermediate space. This airflow caused by temperature differences and gravity weakens the air cushion’s strength as an insulator. Temperature-humidity sensors were installed around the building to study the phenomenon. The conditions were monitored for about a year.

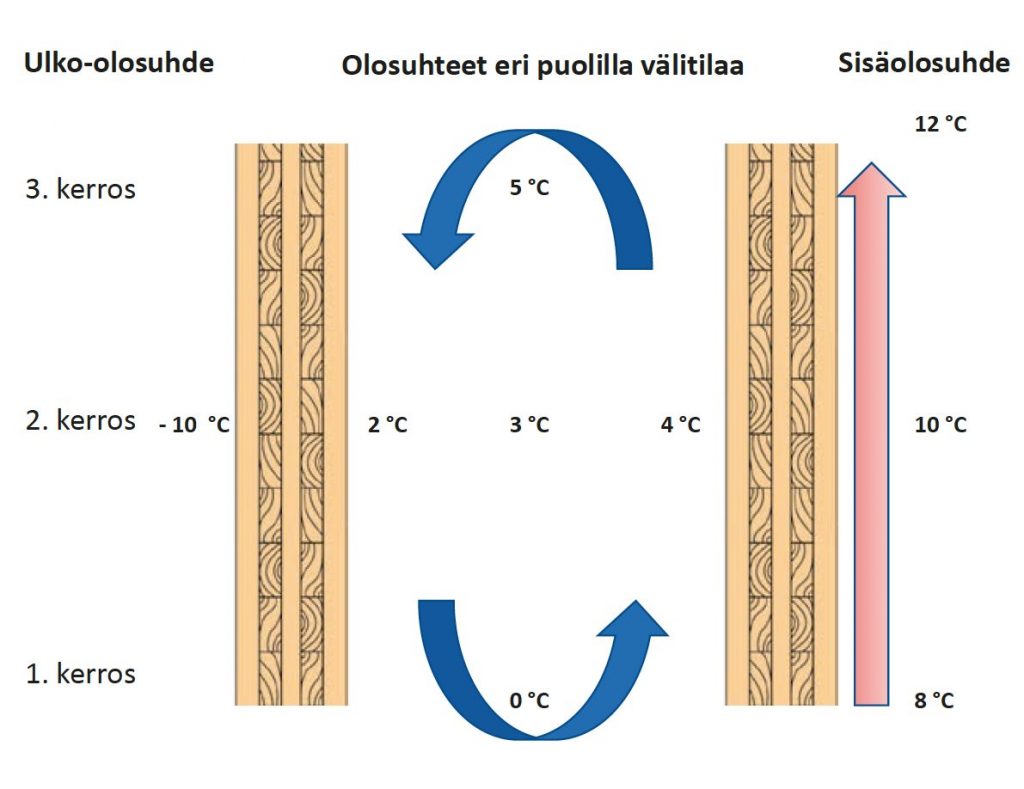

How convection flows are formed

In Meteorite House, convection occurs because of the temperature differences between the exterior and interior shell of the intermediate space. In the winter, the exterior is cold and the interior is warm. As a result, the interior surface warms the air in the intermediate space. This air becomes lighter and rises, while the heavier air chilled by the exterior flows downwards. This is how a convection flow forms and circulates along the wall surfaces. Figure 2 illustrates the presumed convection flows and the measured temperatures from December 2019, when it was freezing outside and only maintenance heat was used inside (building not in use yet). Although convection impairs the air cushion’s function as an insulator, the buffering effects of the airspace can be seen in the long-term graph (Graph 1). The absorption capacity of the structural solution evens out the most abrupt temperature fluctuations. Based on the study, the air-insulating structures in the intermediate space could be divided into smaller sections to control convection, which would improve the insulation capacity by controlling the flue effect. However, this solution requires careful design of the building technology, which would need to prevent moisture condensation on structures and eventually remove any accumulated moisture.

Convection also affects the inside of the Meteorite House: A continuous open space runs from the bottom to the top in the middle of the building, and air warmed up at the bottom becomes lighter and rises upwards. This leads to a temperature difference between the upper and lower floors. To ensure the comfort of eventual residents, this phenomenon needs to be taken into account in the design.

The second research topic: CLT surface treatment

Surface treatments were another CLT construction research topic. The most common solution in CLT construction is to cover the wood surface with separate cladding. This is because CLT is classified as use class 2, meaning it can only be used outside in covered spaces where it is well protected from getting wet (for example, in attics). However, glued wood products, which are quite similar, are traditionally classified as use class 3 (and used in log walls, for example). The only difference between CLT surfaces and corresponding log structures is that CLT surfaces are finished at the factory.

In the Meteorite House, the exteriors of the CLT materials were left exposed to the weather. Before the surface treatment agents were selected, different types of translucent wood preservatives and their life-spans were studied in the laboratory of the Karelia University of Applied Sciences. CLT samples were exposed to weather first in a weather cabinet and then outdoors. The results demonstrated that traditional wood treatment agents also work on finished CLT surfaces. No significant differences between the surface treatments were found in the weather cabinet test, and treatments are likely to work even better on sanded surfaces than planed ones.

All the modern treatment agents lasted reasonably well on the surfaces. No significant differences were detected. Slightly more resin runoff was observed in dark colours than in light ones. No difference was observed in the number of cracks. Indeed, this may have been due to the small size of the samples. Traditional tar agents were also used to treat a few samples for comparison purposes. Compared to the modern treatments, tar had a shorter lifespan and would require more frequent applications, at least based on this test.

At least one CLT manufacturer in Finland now offers a planed CLT variant. This product is based on the same principle as finely sawn lumber. Surface treatments are likely to adhere even better on suitably rough surfaces. By switching to planed CLT in facades, the lifespan of CLT surface treatment agents is likely to improve further.

By monitoring Meteorite House during its actual use, it became obvious that the most critical CLT parts exposed to weather should be covered with sheet metal or felt structures. This was also done in the Meteorite House. For other components exposed to the weather, it is very important to carefully design water drainage outwards at the joints and seams.

Conclusions: From Meteorite to the Kosmos collection

According to the contractors, designers, and the developer Ulla-Maaria Koivula, much was learned from this project. New information and experiences was gained on not only the material’s durability and structural use but also on its manufacturing, logistics, and use as an interior design material. The Meteorite house was drawn up in 58 different variations prior to construction. The brainstorming on new forms and possibilities has continued on Meteorite’s third floor. This now serves as a meeting place for those interested in wood construction and as a workspace for the owners.

“Meteorite is a a polygonal CLT building prototype, a kind of functional wooden sculpture,” says Koivula. According to her, the refinement of the idea has continued together with Ateljé Sotamaa and expanded into a collection of modern wooden buildings suitable for nature tourism and remote working. Model houses will be constructed on the same Koivula plot, near Meteorite.

ULLA-MAARIA KOIVULA is the founder and CEO of the educational technology company ThingLink and the producer of a new Kosmos product collection focusing on functional wood sculptures. Previously, Koivula has worked e.g. Director of the Design Research Institute, on the board of Pro Puu ry and Tapio Wirkkala Rut Bryk Foundation.

VILLE MERTANEN works at Karelia University of Applied Sciences in research and development positions in wood construction. In recent years, in addition to wood construction, the emphasis has also been strongly on research and teaching in low-carbon construction. In addition to the University of Applied Sciences’ own investment, research activities at Karelia University of Applied Sciences have been carried out with project funding, and the Meteorite studies were part of the measures of the Wood Construction – Low Carbon Construction Solutions project.

The article has been published in October 2021 in Wood magazine 2/2021.

- Read the whole Wood magazine 2/2021.

- The next magazine will be published in the spring of 2022. Subscribe it now.

- Articles selected by Wood Magazine advertisers are published as e-articles in addition to the print magazine.