Sound Insulation in Wood Buildings

The article has been published in June 2021 in Wood magazine 1/2021.

Read the article in Finnish: Ääneneristys puutalossa

Text and pictures: Tero Lahtela

Acoustic design plays an important role in wood buildings because it significantly effects how building component layers are structured and how joints and other couplings are made between building components. This means that architects and other designers working on structures and building services need to understand the basics of wood construction acoustics. The structure types and joints selected for a site must be acoustically correct, and the decisions need to be made as early as the predesign stage to avoid redesign and additional costs later on in the project. A wood construction site should always have an acoustics designer.

Acoustic and fire safety design go hand in hand

In the structural components of wood buildings, sound insulation is primarily based on plate-like surfaces that are separated with an air gap. Gypsum boards are a popular solution, forming a plate-like surface that has sufficient mass to serve as a sound-isolating building component. Gypsum board is also a prominent feature of wood building fire safety design. In other words, it makes sense to design acoustics and fire safety at the same time so that the building components can meet the acoustic and fire engineering requirements using the same boards. Acoustics should be handled first, since the number and location of boards is more relevant to acoustics than to fire safety.

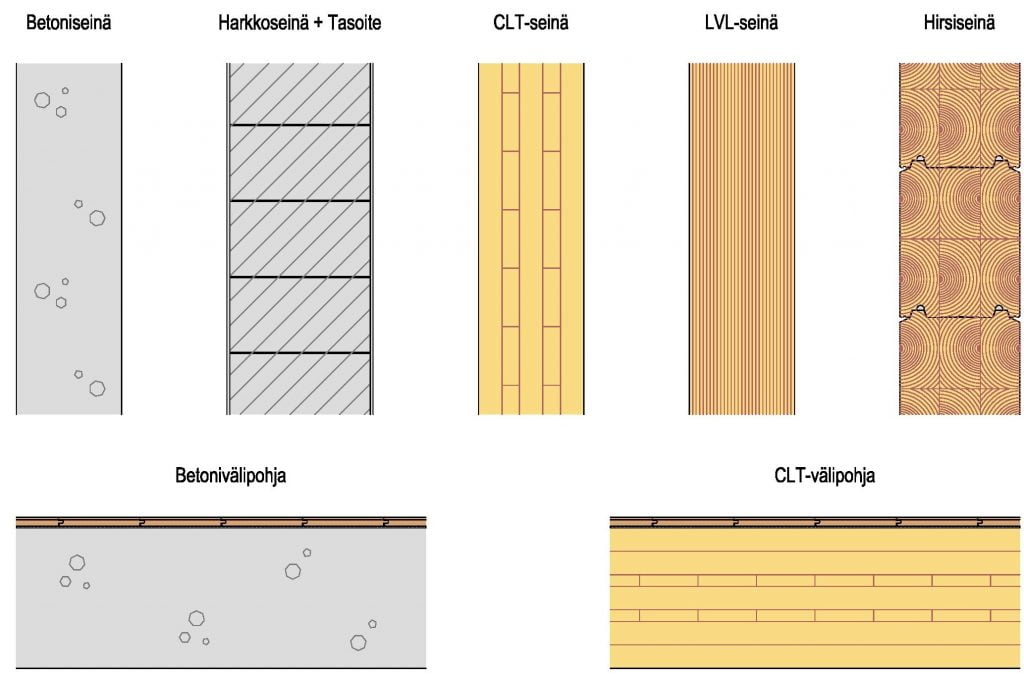

Single-layer acoustics

Acoustic structures are considered to be single-layer when the same material is used throughout the structure or when different layers of materials are so closely bound together that they vibrate as a whole. The structure’s mass, stiffness, air tightness, and the impact of lateral displacements are the relevant factors in the design of airborne sound insulation for single-layer structures. In addition, the flexibility of surface structures (for example, flooring) is relevant for step sound insulation in single-layer structures.

The mass and rigidity of single-layer wood structures are typically too low to meet modern sound insulation requirements in buildings. For example, a single-layer solid wood wall should have a thickness of at least 600 mm to match the airborne sound insulation of a 180 mm thick concrete wall.

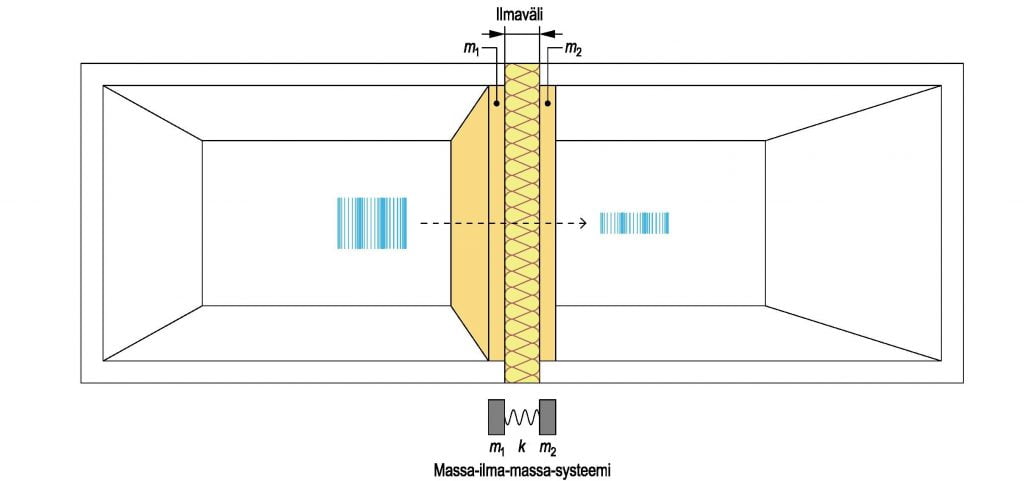

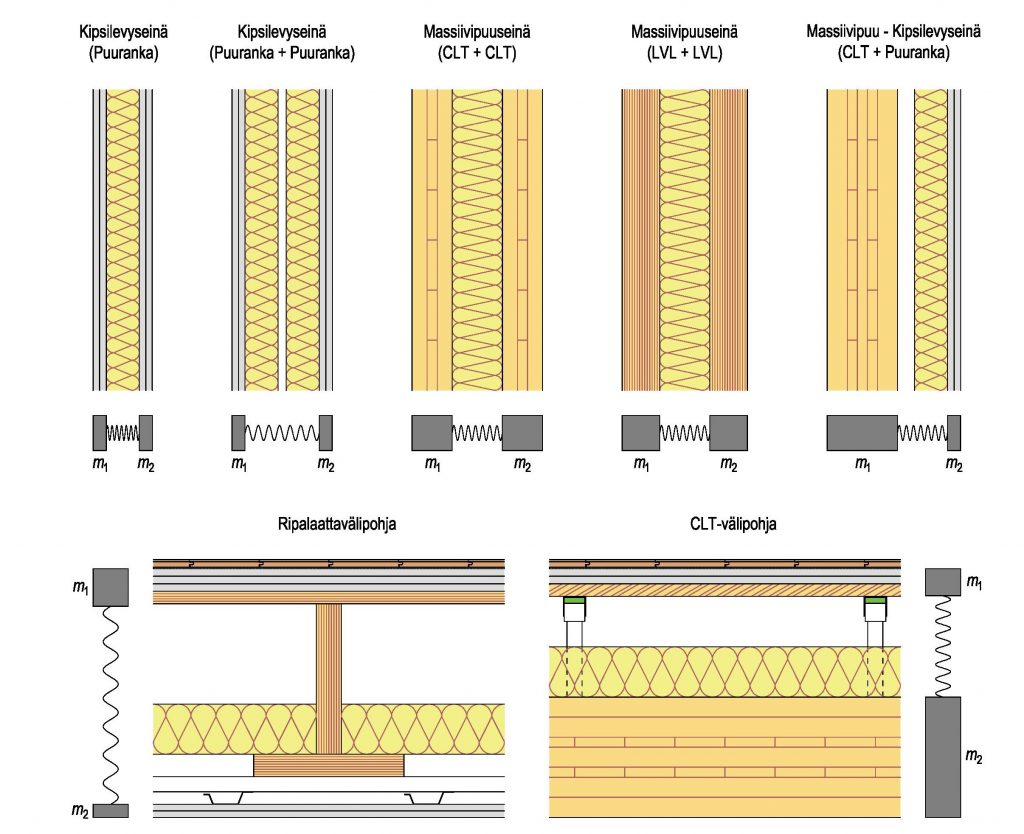

Dual-layer acoustics

Acoustic structures are considered to be dual-layer when the structure has two plates (m1 and m2) with an air gap (k) between them. The air gap in dual-layer structures is called a spring, and its effectiveness as an insulator depends on the thickness of the air gap. The air gap acts as a spring when it is thicker than the wavelength of the sound applied to the structure. The looser the spring, the less it transmits vibration between plates m1 and m2 and the better the airborne sound insulation of the structure. In other words, thin air gaps do not act as springs. Rather, they connect the plates to each other, which causes the airborne sound insulation of the structure to deteriorate.

The plates can be attached to the same frame (framework), which means the frame mechanically connects the plates to each other. These kinds of structures do not provide significant airborne sound insulation because of the mechanical connections mentioned above.

The ideal dual-layer structure has plates that are completely separated from each other (double framed), with the masses only connected to each other by a large air gap (loose spring). Even if the structure is light, an ideal mass-air-mass structure such as this can lead to incredibly efficient increases in airborne sound insulation above the resonant frequency of the structure.

However, it is not easy to create an ideal dual-layer structure in buildings because plates may be mechanically coupled; for example, where building components are joined. Similarly, in intermediate floors the load-bearing frame may connect the plates to each other.

As noted above, single-layer solid wood structures are often unable to provide adequate sound insulation in buildings. This is why wooden building components that are intended to provide sound insulation must almost always use dual-layer acoustic structures. This applies to walls and intermediate floors alike.

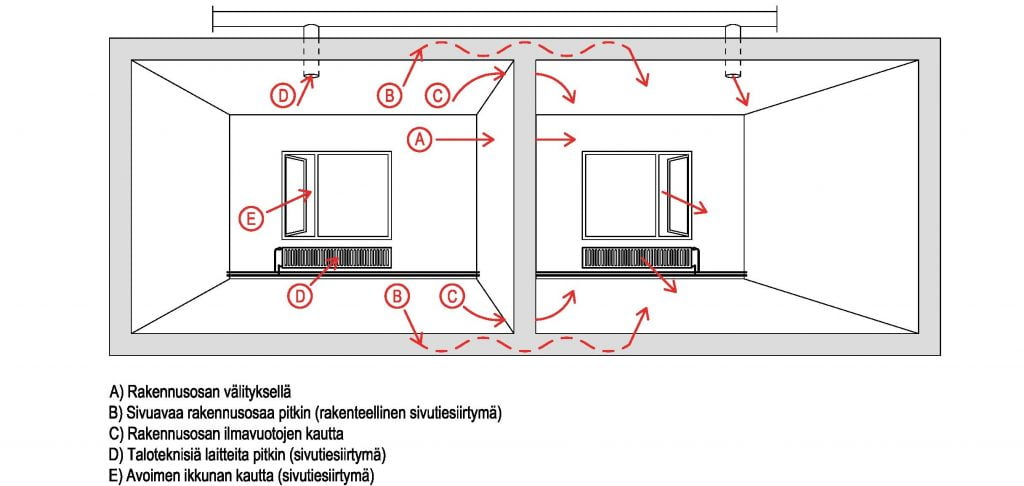

Lateral displacement

Lateral displacement is one of the ways in which sound propagates between spaces. Lateral displacement occurs when a building component extending from one space to another carries sound (structure-borne sound) from one space to another. Lateral displacement is a bigger challenge in wood buildings than in concrete buildings for several reasons:

- Wooden building components do not have sufficient mass and stiffness on their own to reduce lateral displacements.

- Since there are so many wood structure solutions available, the design solutions for decreasing lateral displacement are case-specific.

- Joints in wood structures have more structural components, which means that small changes to structural components can have large effects on lateral displacements.

In wood-framed buildings, building components and connectors can cause lateral displacement if the connectors extend from one space to another. One example of a connector is a steel plate used to anchor the building frame. The taller the building, the more connectors required in the building frame and the stiffer they need to be. This is why the acoustic design challenges for connectors increase with the height of the building.

The sheer number of connectors on offer for wood structures increases the challenge, especially since they vary from one wood building system to the next. This means that connector design must always be case-specific. From an acoustic perspective, the connectors act as dot-like lateral displacements. When connectors are located in the wrong place however, they may transmit structure-borne sound over a very wide area of the building frame.

In wood-framed buildings, lateral displacement is typically prevented or its effect reduced by cutting off building components extending from one space to another, by using vibration insulation at the building component connector, or by using slab cladding on building components. In residential buildings for example, intermediate floors must be cut off between apartments to prevent the transmission of intermediate floor vibration. This also removes a path for horizontal lateral sound displacement.

However, when stiffening horizontal building components are cut off like this, the cut off site needs to have the right kind of connectors. The building frames still need to form an integrated whole from a stiffening perspective, and this needs to be taken into account in the design. Vibration isolators are typically used for wall and intermediate floor connections and connectors.

The design needs to account for the effect of the vibration isolators on the strength, stiffness and general performance of the connection. The isolators themselves can be made from a polyurethane-based material, for example, and dimensioned for the load applied to them. Vibration isolators need a small amount of compression (about 1 mm) to work, but too much compression prevents the vibration isolator from working. The colours of the various vibration isolators available indicate their properties, which makes it easier to define and indicate the various vibration isolators in designs.

New manual for sound insulation design in wood buildings

In May 2021, Puuinfo published a guide to sound insulation in wood houses. The guide replaces a similar one published in 2004 and contains the key information needed to design sound insulation in wood buildings. The aim is to provide practical information on sound insulation design and to illustrate the acoustic performance of wood building components. The guide covers building systems currently used in wood buildings, for frame structures and solid wood structures alike.

The guide is intended to serve as a design tool for architectural, structural, and building services designers to help them implement the right types of design solutions as early as in the predesign phase. The guide to sound insulation in wood houses is also well suited for use as teaching material in educational institutions in the field.

The guide has been updated to comply with the provisions of the Finnish Ministry of the Environment’s Decree 796/2017 on the sound environment of buildings, which entered into force on 1 January 2018, and the amendments presented in Decree 360/2019.

To view the digital version of the Ääneneristävyys puutalossa (Sound Insulation in Wood Houses) guide, visit puuinfo.fi/suunnittelu/ohjeet.

- Read the whole Wood magazine 1/2021.

- The next magazine will be published in October 2021. Subscribe it now.