Design automation promotes carbon efficient construction

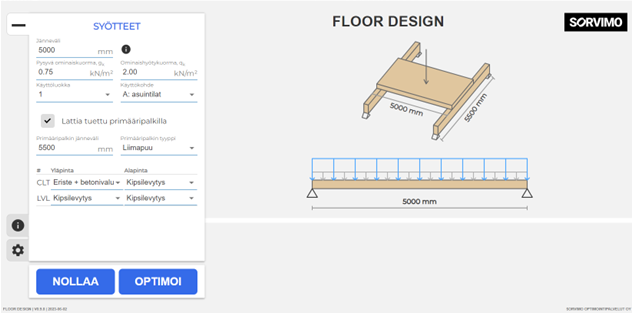

The carbon efficiency of a construction project can be significantly improved by automating structural design in appropriate stages of the project. A new online tool, Floor Design, can help builders do just this while helping them understand the potential of wood construction. Many people don’t even realise that it’s possible to automate the design of larger structural units in large-scale buildings – or even the design of entire buildings. With this new tool, a user can easily check what kind of wooden intermediate floor can be used with a specific span and how that floor’s carbon footprint compares to concrete. The decision-making in the construction project becomes more transparent, and the competing options can be easily compared. At its best, the tool can help decision makers choose the most carbon efficient structures for their projects.

Read the article in Finnish here.

In wooden construction, a project’s carbon footprint and other environmental impacts greatly depend on the amounts of material used. Decisions made during structural design have far-reaching impacts, and the designer’s skills influence how much the calculations leave room for risk and how large a carbon footprint the load-bearing structures will have. However, the designer can significantly improve carbon efficiency by automating suitable parts of the structural design.

In the early phases of a project, the new Floor Design tool can help visualise the carbon footprint of the upcoming building’s load-bearing structures. The tool is intended for the proposal design phase, and users do not need structural design skills or other specialised expertise to use it. Once the building’s intended use and main dimensions are known, the user is only a few clicks away from seeing which structural options suit the building’s load-bearing frame, and what the carbon footprint of these structures would be. This means that everyone involved, not just the structural designer, can have more information at their fingertips and form informed opinions on the various structural options.

Floor Design has been developed for the design of intermediate floors, but it serves a greater purpose at the same time. The choice of intermediate floor is typically integral to a building’s structure, and it essentially determines most of the remaining frame materials and their associated carbon footprints.

Floor Design also includes the Eurocode 5 guidelines and a full dimensioning review according to the Finnish design guidelines RIL 205-1-2017. In addition, the tool’s analysis of CLT structures is based on the precise theory of layered beams, enabling it to process extraordinarily complex CLT cross-sections.

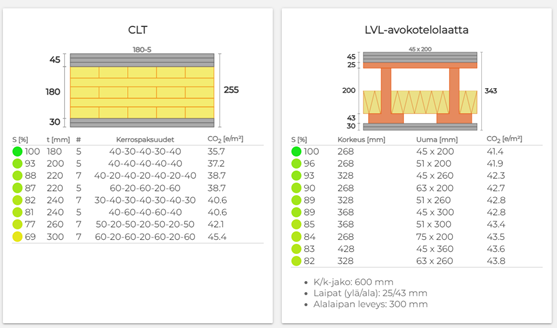

The key feature of Floor Design is its ability to calculate the carbon footprints of diverse types of intermediate floor structures, making their comparison transparent. The tool can even include the surface layers in its calculations. Based on the data entered by the user, the tool provides CLT and LVL slab structures that are optimised for their carbon footprint and meet design regulations. For reference, the tool provides a table-dimensioned hollow slab solution.

AUTHOR:

Sami Pajunen works as a technical expert in Sorvimo optimointipalvelut and as a professor at the University of Tampere.

Floor Design is freely available at www.sorvimo.com/tools.

Floor Design was developed by Sorvimo Optimointipalvelut Oy as part of the SorviCO2 project, which received funding from the Ministry of the Environment’s Low-carbon built environment program.