Tall wooden buildings: potential, benefits, challenges, and prospects

In recent years, larger and taller wooden buildings have been built all around the world. In this article, Post-doctoral Researcher Hüseyin Emre Ilgın and Professor Markku Karjalainen from the Tampere University School of Architecture discuss the pros, cons, and possibilities of tall wooden buildings.

Text: Hüseyin Emre Ilgın, Markku Karjalainen, Tampereen yliopisto Photos: Voll Arkitekter AS, Ricardo Foto, ARTEC, Michael Elkan, Acton Ostry Architects, Arkkitehtitoimisto Arcadia Oy, Thornton Tomasetti

Read the article in Finnish: Korkeat puurakennukset: mahdollisuudet, edut, haasteet ja näkymät

In the modern era, wood has mostly been used in low-rise and auxiliary structures while steel and reinforced concrete replace wood in larger structures and their load-bearing parts. However, engineers now need to consider environmental factors and can benefit from advances in engineering sciences and construction technologies that allow wood to be used in more building components than was ever dreamed of in days gone by. Taking these two developments together, engineers have a greater motivation to design and construct wooden buildings that are larger and taller than ever before.

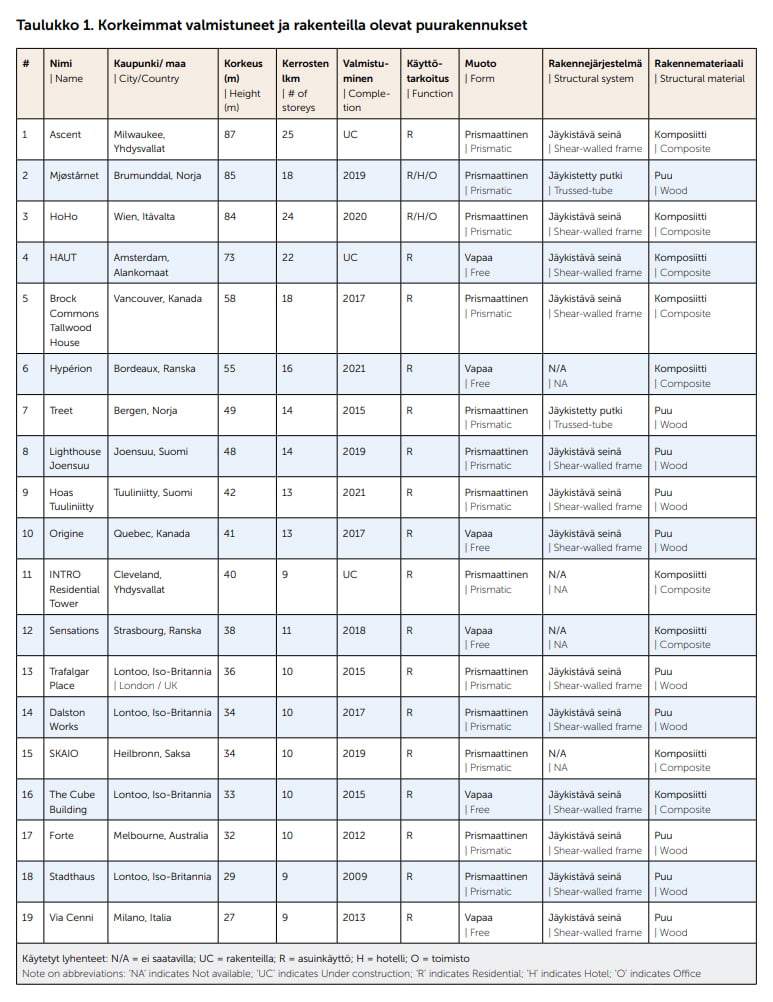

In recent years, many countries around the world have witnessed an accelerating trend in the construction of high-rise/tall (9-storey and more) wooden buildings using engineered timber products (ETPs). These buildings are reaching unprecedented heights. Examples include the 25-storey, 87 m high Ascent (Milwaukee, under construction), the 18-storey, 85 m high Mjøstårnet (Brumunddal, 2019), the 18-storey, 58 m high Brock Commons Tallwood House (Vancouver, 2017), the 14-storey, 49 m high Treet (Bergen, 2015), and the 14-storey, 48 m high, Arcadia Oy Arkkitehtitoimisto-designed Lighthouse Joensuu (Joensuu, 2019. See table 1 for tallest wooden buildings completed and under construction. After more than two decades of experience, designers have the confidence to ”go tall” in Europe and to invest significant resources in finding practical solutions for wooden structures in regions with extensive seismic activity in North America.

Potentials and benefits

Developments in the wood construction sector include the introduction of ETPs. At the material level, cross-laminated timber (CLT), laminated-veneer lumber (LVL) and glulam timber (GLT) can be used for floors or walls and have changed the industry substantially.

At the connector level, self-tapping screws (STSs) and glued connections offer alternative methods that go beyond the limits of the traditional dowel approach. At the system level, new hybrid solutions such as pre-stressed self-centring systems, steel moment frames with CLT infill panels, massive wood balloon frames with steel joints, wood-concrete jointed frame concepts, and wood-concrete composite floors or wood-steel hybrid systems are increasing their footprint in the industry.

From a construction perspective, key benefits include reduced on-site assembly time due to a high degree of prefabrication and lower energy demand for delivery and assembly because of the rapidly increasing share of prefabrication, lighter wood prefabricated components, and dry construction technology. Wood can also be fitted with additional layers to complete the building envelope, including prefabricated elements, services, and finishing. Just for comparison, note that wood has a density of approximately 500 kg/m³, while concrete’s density is 2500 kg/m³ and steel is 8000 kg/m³.

Challenges and solutions

Some risks from the accelerating trend towards tall wooden buildings include earthquake resistance, stiffening, fire safety (wooden buildings over 2 storeys often require a sprinkler system), long-term durability and maintenance of the wood facades, and sound insulation. In addition, cost is still seen as a factor with wood. For example, estimating costs can be difficult in the USA because massive wood systems are relatively new. This means contractors are understandably sceptical of benefits like competitiveness, unless they are among the few people involved in previous projects in the region.

However, an increase in the number of tall wooden buildings will contribute positively to both construction experience and cost competitiveness. This will result in both an increase in the number of willing developers and contractors and a decrease in construction costs. When considering the environmental benefits of wood as a building material, using wood may be a more logical option then steel or concrete in high-rise construction when facing the increased demand for buildings caused by intensifying urbanization. There are also many places where wood can be used as a substitute for concrete or steel in building construction. Thanks to the fire-resistant and fire-retardant paints and treatments available today, the fire classes of wooden structures can be increased from D to B, which makes them safer.

In contemporary tall wooden buildings around the world, asymmetric geometries, more exposed wood, and the effort to increase the share of the transparent envelope is often accompanied by a race to reach greater heights. As a reflection of this trend, the architectural design of the new generation of wooden buildings shows more geometrical differences. This diversity includes irregular vertical extensions formed by changing floor slabs, division of the basic structural grid into smaller segments, and the asymmetrical configuration of facade openings such as windows and balconies.

Another geometric parameter affecting buildings and their stability is the location of the building core relative to the building mass. Note that elements in the architectural expression of buildings require a range of technical and structural issues to be addressed and resolved. Energy efficiency and environmental performance are also heavily influenced by the architectural design of a building.

A combination of wood and other structural materials such as reinforced concrete, also known as hybrid systems, can be used in the tallest wooden buildings to significantly increase lateral stability. In other words, hybridization with a reinforced concrete core aims for better structural safety and robustness by providing efficient horizontal stiffening, which becomes more and more important with increasing building height.

Recently, there has been an increase in tall wooden structures using additional RC structural cores to provide lateral stability, as the wooden structure alone cannot handle all the lateral loads. Examples include the 25-storey, 87 m high Ascent (Milwaukee, under construction), the 24-storey, 84 m high HoHo (Vienna, 2020) and the 18-storey, 58 m high Brock Commons Tallwood House (Vancouver, 2017).

Despite the growth in and the numerous advantages of wood construction, tall wooden buildings still make up a relatively low proportion of tall buildings when compared to their concrete and steel counterparts on a global scale. While the extensive forests and well-developed prefabricated wood element manufacturing industry in many European countries also creates a lot of potential, the tall wooden construction share of this opportunity remains partially untapped. When used in high-rise construction in particular, wood’s complex structure and difficulties stand out.

These include sensitivity to moisture, its lightweight and orthotropic nature, low stiffness, brittleness, system effects, size effects, and time effects. The design of particularly tall wooden buildings is complicated further by their many structural limitations where design considerations such as climatic conditions, exposure to wind, and seismic hazards are largely dependent on the characteristics of the location. Designing for structural strength in tall wooden buildings is still poorly understood due to the complex properties of wood and the difficulty in testing large assemblies. This all makes it very difficult to predict the behaviour of tall wooden buildings in the event of damage.

Wood-specific structural challenges

From a structural design perspective, highrise buildings show a greater susceptibility to lateral load risks caused by wind and earthquakes relative to low-rise buildings because of their greater height. When designing tall buildings, it is more difficult to estimate lateral loads than vertical loads. These lateral loads are important as they play a decisive role. Compared to concrete and steel structures, wooden structures have lower stiffness and mass density, which means that horizontal oscillation and dynamic behaviour must be considered when designing tall wooden structures. Base shear forces due to wind loading in tall wooden buildings are normally greater than those caused by earthquake loading due to the high flexibility of these buildings.

During the structural design phase for tall wooden buildings, consideration must be given to the effects of the wind load at the ultimate limit state and to controlling wind-induced lateral displacements at the serviceability limit state. People’s responses to wind-induced vibrations; otherwise known as occupancy comfort, is also an important criterion when designing tall wooden buildings. Just like with tall buildings constructed with traditional materials, the choice for the structural system is an important parameter in tall wooden building design, and providing structural stability plays an important role in the development of these structures.

Tall wooden buildings can use established structural systems such as solid panel systems with basic load-bearing members and frame-panel structural elements made of CLT where structural stability is based on the composite movement of the wooden linear frame elements and sheathing boards. This is why selecting an appropriate sheathing largely depends on the number of storeys and the lateral loads on the wall elements. When comparing vertical and lateral load-carrying capacities, massive panel structural systems usually show significantly higher tolerances than frame-panel systems. This results in designers usually preferring CLT wall elements when planning buildings with more than 3 storeys.

Some prefabricated multi-storey wooden buildings use reverse layouts for cross-laminated sections: cross-laminated wall elements are placed on the façade with framed wall elements in the interiors. These kinds of solutions are particularly preferred in midrise wooden structures, as they are exposed to the highest torsional forces on the building perimeter due to the floor asymmetry. Most of the tall wooden buildings planned before 2009 were designed using cross-laminated structural systems, as is the case with Stadthaus (London, 2009).

In addition, advanced structural systems such as braced frames that use additional members and/or other elements are capable of withstanding higher gravity and lateral loads. In typical braced frame solutions, the braces are only subject to axial forces, which is why they can significantly supplement the bearing capacity of the frames. The addition of braces also results in a significant increase in the overall rigidity of the system, which reduces the deflection to meet the allowable drift limit requirements.

These systems, which are also known as trussed-tube systems, have been used in tall buildings for a long time. Two spectacular examples using wood are Mjøstårnet, currently the tallest wooden building in the world, and Treet. These structures are built in less seismically active areas. Their structural design was governed by wind loads rather than earthquake loads.

One of the larger challenges in encouraging designers to use or select more wooden construction systems is a lack of specific guidelines with design practices. When it comes to designing seismically safe wooden buildings for example, Eurocode 8 currently lacks sufficient guidelines. Robustness, which is the ability to withstand events without disproportionate structural damage, is also an important characteristic of any building. This characteristic is critical when it comes to large or unusual structures, whose behaviour is not fully understood and where the risk of a disproportionate collapse is high. The tall wooden buildings undergoing a renaissance with the technological advances in engineered wood products today fit this definition of a large and unusual structure. Research and understanding of structural robustness is currently mainly limited to reinforced concrete and steel structures. Most building codes do not provide explicit guidance on robustness design, particularly when it comes to wood. Current initiatives are also exploring ways to apply performance-based seismic design to create durable tall wooden buildings in regions with a high degree of seismic activity.

Conclusions and prospects

A successful massive wooden building design requires early coordination between the design team and the contractors, early identification of wood component suppliers, and optimising materials, panel sizes and grids, and more. Architects, structural engineers, and other key professionals in the construction industry should discuss all these issues in the initial design stages to produce more optimized and cost-effective construction methods for use in daily practice. Tall wooden building design in particular requires an approach emphasising synthesized architecture and interdisciplinary methods that covers environmental, structural and energy-based issues.

Any comprehensive quality assessment of tall wooden buildings should also consider energy efficiency, appropriate architectural and structural designs, the nature of the indoor environment, and future climate scenarios. Improved tall wooden building design will become an important factor in optimizing the energy efficiency of buildings.

As more projects are completed, more business case data becomes available to illustrate the many cost-related properties of massive wood elements and its ultimate competitiveness with other building materials. The perception that wood is a suitable material for such structures will improve with each new project. Direct incentives such as demonstration projects and competitions should go a long way towards removing barriers. In this sense, massive wood element cost and design optimization checklists, construction management training, and massive wood element installer training will contribute to overcoming these barriers.

Maintaining the ongoing activities and favourable conditions can be expected to help wood take its place as cost competitive, commonplace material for high-rise construction in the world in the near future.

Hüseyin Emre Ilgın received his Ph.D. (2018) in Building Sciences about tall building design in Architecture from METU in Ankara. Since December 2019, he has been conducting post-doctoral research on wood construction at Tampere University. Now Dr. Ilgın works as a Marie Skłodowska-Curie postdoctoral research fellow on dovetailed massive wood board elements.