Wood fibre board

Wood fibre board is made of wood fibres, which are connected to each other through the effect of heat and pressure. The adherence of the fibres to each other is achieved through couching and the wood’s own adhering properties. The fibres on the surface layer of the board are often more ground up than those in the middle layer. This gives the board an even and compact surface. Glue and other additives can be used to improve the properties of the board and to even out differences in raw materials and manufacturing methods. The main raw material for fibre board is, however, wood fibre, and the amount of additives is usually less than 1%.

Paraffin is normally used as a water-repellent adhesive. Starch, artificial resin and hardening oil are used as binding agents to improve the strength. Veneering board, paper, fabric, plastic, woven glass fabric, metal or cork are used as coatings for wood fibre board (for most common dimensions, see figure 1).

Standard wood fibre board can be divided into two main categories:

- porous

- hard

In terms of its basic properties, wood fibre board is comparable to wood and possesses all of wood’s best features: strength, toughness and warmth. It also has the following benefits, owing to its method of manufacture:

- homogeneous, no grain direction

- dense but breathes

- easy to work with and quick to install

- acts as additional thermal insulation

- competitively priced

Many wood fibre board products are classified in surface material emissions class M1. Material classification includes the limit values for the emissions of building materials meant for interiors, as well as their classification. Class M1 contains emissions-tested materials, whose emissions of impurities are within the most stringent requirements.

Wood fibre boards as part of a building frame

Wind-shield boards

By increasing the resin and wax in porous wood fibre board, it is possible to improve its weather-resistance properties. Board treated in this way is particularly suitable as a wind-shield material for wood-framed external walls. It also gives the wall structure more rigidity.

Boards meant for wind-shield purposes are manufactured in thicknesses of 12 and 25 mm. The most common board sizes are 1,200 x 2,700/3,000 mm. Thanks to its strength and insulating properties, 25 mm-thick wind-shield board in an external wall structure is very suitable for so-called single-frame construction. As a result of the low heat conductivity of the boards, they form a cold break in structures and improve their thermal insulation properties.

In addition to external wall wind shields, they can also be used as roof wind shields. In sloping roofs, especially when using blown thermal insulation such as wood fibre wool in so-called cavity blowing, weather-resistant wood fibre boards are very suitable as board for the upper surface of the cavity.

Weather-resistant wind-shield boards are also suitable as a double floor board for a wood-framed, load-bearing base floor in the subfloor space, on top of which the base floor thermal insulation is installed.

Interior lining boards

Wood fibre boards suitable for interior lining are:

- all standard wood fibre boards

- highly processed fibre boards meant for interior lining, so-called interior boards

Matters to be taken into account in interior lining:

- Wood fibre board is also very suitable as interior lining at summer cottages. Wood fibre board is, however, not recommended for wet rooms or as a base for tiling.

- In dry interior spaces, the moisture dynamics of fibre board are slight. The ’butt joints’ of porous wood fibre board can also be completely smoothed over, giving a uniform seamless wall surface.

- In interior lining, porous wood fibre boards and perforated hard wood fibre boards are also very suitable for sound damping.

Untreated basic board

Porous wood fibre board (untreated basic board) is suitable for the lining of both interior walls and ceilings, and for the additional interior thermal insulation of exterior walls. 12 mm-thick board can be used for this in either one or two layers, or a 22 mm-thick board can be used. If you use two layers, make sure that the vertical joints of the boards do not overlap. Untreated wood fibre board belongs to surface class E.

Wood fibre boards for industrial use and downstream products

Wood fibre boards used in industry (especially the furniture and door industries) are usually hard wood fibre boards (hardboards) or further processed downstream products coated in different ways.

Painted hardboards are chiefly made for the carpentry and furniture industries. They are also suitable for exhibition stands and for interior decoration. Their sizes are usually 1,220 x 2,440/2,745/3,050 mm and thicknesses 3.0 mm, 4.8 mm or 6.0 mm.

In addition to the above, veneering board, paper, fabric, plastic, woven glass fabric, metal or cork can also be used as coatings for wood fibre board.

Other downstream products made of wood fibre board are chiefly (standard) boards made for a specific purpose and coated or ‘impregnated’ in different ways, depending on the application. For example, hardboards are supplied painted, sawn-to-measure, oil-quenched, coated in different ways and perforated, based on customer needs.

MDF (medium density fibreboard) board is made by compressing wood fibres with glue. The amount of glue varies depending on the product. MDF board differs from other types of wood fibre board in its method of manufacture and glue content. Moreover, the wood fibres used in the board are finer-grained. MDF board is particularly used in the furniture industry, but veneer-surfaced or painted batten-strip and panel products meant for interior decoration are also made from it. MDF board is not manufactured in Finland.

Ordering

When ordering wood fibre boards, the following information should be given:

- thickness as a nominal thickness (mm)

- board size (mm x mm)

- board type (e.g. hard wood fibre board)

- for coated wood fibre boards, either the product name or the quality of the covering of both surfaces, the thickness (g/m²), the methods of protecting the edges and colour.

- possible additional machining and its location (e.g. perforation)

Storage

During transportation and storage, the boards are protected from dryness and wetness, dirt, sunlight, ground contact, dents and scratches. The boards are stored face down on a flat base. If necessary, supporting timber is used at intervals of 0.5 metres. A pile of boards is covered with a protective sheet.

Hard and oil-quenched wood fibre boards are usually moistened before installation. About 0.25 l/m² of water is needed for this. The boards are stored in a pile with the moistened surfaces facing each other and wrapped in plastic for about three days. Installation must be done while the boards are still moist.

Semi-hard and porous wood fibre boards should not be moistened with water. They should be aired in a room at least as moist as where they will be finally installed. When being aired, the boards are kept apart from each other using separating strips, and stacked against a wall, for example. They should be aired for 2-3 days.

Working and machining

Sawing

A table-mounted or portable circular saw, for example, is suitable for sawing the boards. Smaller sawing jobs can also be done with a regular hand saw. Contour sawing can be done with a jig saw. Porous wood fibre board can also be cut with a sharp knife.

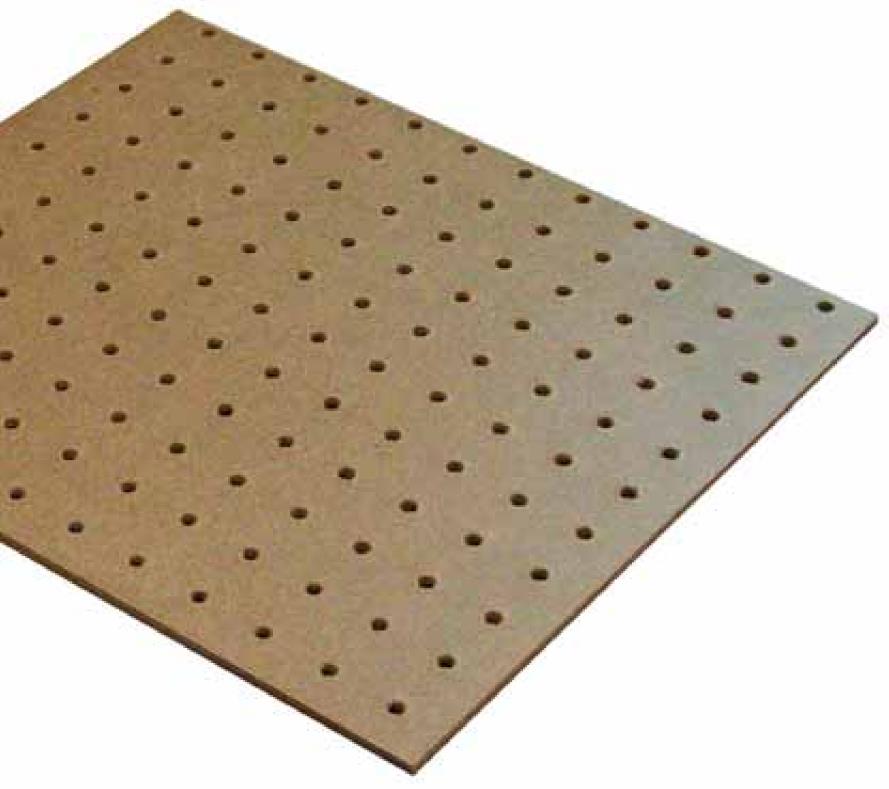

Perforation

If necessary, hard wood fibre boards used in interior lining can also be ordered ready perforated. Perforated boards are normally used for reasons of acoustics or appearance. Perforation is done mechanically and, when ordering the boards, in addition to the above-mentioned instructions, the hole size and distance between the holes should also be mentioned. The hole size may be, for example, ø 4.8 or 7.1 mm and the distance between the holes 19 or 25 mm. Some suppliers might have certain standard hole sizes and distances, so it is advisable to check the perforation alternatives before ordering.

Bending

Curved surfaces can also be made with wood fibre board. Only hard fibre boards (so-called hardboards) are suitable for the purpose, and the thickness should be no more than 4.8 mm. An indicative bending radius is about 50 times the thickness of the board so, for example, the bending radius of a 4.8 mm-thick board is about 250 mm. Bent boards are suitable not only for interior lining but also for making curved concrete moulds, among other things. A bent board is always fastened with screws.

Fastening

Wind-shield boards are fastened to a wooden base with hot-galvanised wire nails (or square brackets). The length of the nails should be at least 35 mm for a 12 mm board and 60 mm for a 25 mm board. The distance between fastening points at the edges of the board is 75-100 mm for a 12 mm board or 200 mm for a 25 mm board and, in the centre, 150-200 mm for a 12 mm board or abut 300mm for a 25 mm board. The distance of the nails from the edge of the board is a minimum of 10 mm. Wind-shield boards are installed in the direction of the frame pillars and are fastened to the frame from all edges.

Porous wood fibre boards are fastened to the wooden base with nails. The length of the nails should be at least 40 mm for a 12 mm board and 60 mm for a 22 mm board. If two layers of 12 mm board are to be attached to a wall, the topmost boards must be fastened with nails 75-100 mm long.

The boards are fastened at intervals of 150 mm on each side and about 300 mm at the centre, with a distance of about 400 mm between the rows of nails. The distance of the nails from the edge of the board is about 20 mm. Hard wood fibre boards are fastened with nails, screws, square brackets and/or glue. The length of nails should be at least three times the thickness of the board, but no less than 30 mm, and the length of screws at least 2½ times the thickness of the board, but no less than 25 mm.

Surface treatment

Particle boards can be painted, wallpapered and laminated. All general products meant for the interior painting of wooden surfaces are suitable for painting the boards.

Hard wood fibre boards are suitable for painting as they are. The painting of porous wood fibre board requires priming, in which the surface of the board is painted with one thin coat of white interior primer or has wallpaper glue applied in advance. Alternatively, boards already primed at the factory can be used.

After priming, the joints of the boards are sanded to a smooth finish (if necessary, a little filler is used on the board joints and nail head indentations). Thin paper ribbon (e.g. from a calculating machine) is wet with water and attached to the vertical joints. The boards are ’wallpapered’ with pieces of waste paper and given two coats of the desired finishing paint. Glass fibre wallpaper or so-called painting wallpaper can also be used for coating (as a base for painting).

Wall surfaces lined with porous wood fibre board can also be wallpapered. If the walls are wallpapered with structural-, vinyl- or duplex wallpaper, priming work is done in the same way as when using waste paper. When using completely smooth and thin vinyl or paper wallpaper, the boards are first coated with waste paper and then wallpapered normally. When wallpapering, any possible special instructions given by the wallpaper manufacturer must also be taken into account.

The re-use and disposal of wood fibre board

Re-use

If the boards are intact and dry, wood fibre boards may be used again on a case-by-case basis. Re-use is the most popular was of ’disposing of’ wood fibre boards.

Disposal

Because wood fibre boards are mainly clean natural wood, they can be disposed of by burying in the ground, composting, taking to landfill or burning. Wood fibre boards with an untreated surface can be burned in a normal fireplace, preferably with other firewood.

Wood fibre board applications

Construction

- wind-shield- and double-floor boarding in roofs

- interior lining

- additional thermal insulation

- concrete moulds and other temporary structures (e.g. building site fences and protective boarding)

Construction industry

- as web plates for beams

- backing plates for fixtures and fittings

- surface material for window frames

Means of transport

- car interiors

Other applications

- packaging

- exhibition and fair structures