Timber construction as an enabler of low-carbon property development

Text: Matti Kuittien, Aalto yliopisto

Different buildings have different impacts on the climate. Furthermore, in addition to the construction providing good heat insulation, the payback time for the finance and energy used, and the carbon dioxide emissions generated in their manufacture should be sufficiently short. Timber construction is high up on the list when it comes to climate-favourable construction.

According to the UN, building construction and maintenance consume around one-third of the world’s energy and produce about a quarter of all greenhouse-gas emissions. By reducing emissions by the built environment we can slow down the climate change brought about by Mankind considerably and at the same time reduce its harmful impacts.In switching to effectively zero-energy building construction, we also change the distribution of emissions during the entire life-cycle of the building in question. Emissions during the use of buildings will be reduced to give better energy efficiency. Correspondingly, the relative proportion of emissions caused by the manufacture of building products and building services equipment will grow. The carbon footprint of a zero-energy building is small only if low-carbon building materials are used in its construction and repair. The same thing applies to energy overhauls of existing buildings. The materials and systems used in repair should be selected so that the costs, energy and greenhouse-gas emissions arising from their manufacture should have the shortest possible payback time. In both newbuild and repair, the impacts of the measures taken throughout the entire life-cycle of the building must always be examined.

The recycling economy depends on renewable materials

A change is taking place in industry towards utilising renewable natural resources and renewable energy. This is being expedited by the decline in oil resources and other non-renewable natural resources as well as by climate change. It is not possible to satisfy Mankind’s growing need for energy and materials with non-renewable raw materials. We are heading for an unavoidable crisis in energy and resources. Resolving this crisis in the space of one generation is an operation which, in the magnitude and complexity of the challenge it presents, is worthy of at least a dozen Nobel Prizes.

The increase in the use of renewable building materials in modern zero-energy construction is a major help in slowing down climate change. In a comparison of the results of 19 international studies, it can be seen that the carbon footprint of a wood-framed building will always be smaller than the carbon footprint of a concrete or steel-framed building, however the emissions are calculated. The carbon footprint produced by the manufacture of a wooden building frame was, on average, 55% of that of the control frame. Many studies also show the major impact of foundations and ground-works. A low-carbon building is easier to construct as a timber-framed building and located preferably on a site where piling or stabilisation is not required. Constructing low-carbon buildings in the future will be goal-oriented teamwork with a dream-team consisting of planner, client, designer, building inspector and building contractor.

If the EU is involved there are going to be standards

Guidelines for calculating the environmental impacts of European buildings can be found in the EN Standards. These set out mutually agreed rules on e.g. calculating carbon footprint and other environmental impacts in an impartial, comparable, scientifically based manner. The Standards also describe a way of drawing up environmental declarations for building products. Environmental declarations are the most reliable way for designers, clients and consumers to compare the ecological aspects of alternative products.

Wood building has been at the forefront while the Standards were being set. The first product group environmental declarations to be drawn up (EN16485) were for wood-based building products. This work was the subject of a joint development project carried out by Finnish Forest Industries and the Aalto University, which produced the first Finnish language guidelines and blank form for data collection to be used in drawing up environmental declarations. The guidelines make it easier for companies to draw up environmental declarations and aim to clarify different interpretations of the Standards. Guidelines and data-collection form have been developed and tested by Metsä Wood, Stora Enso and UPM. The guidelines can be found on the Finnish Forest Industries (Metsäteollisuus) website at www.forestindustries.fi (toimialat/puurakentaminen).

Low-carbon has export potential

At the transition stage from fossil fuels to renewables, there are bound to be conflicts of interests. You can’t win ’em all! Recent years have seen a growing ‘divest-reinvest’ movement, in which major investors withdraw from the fossil-fuel sector and reinvest in environmentally friendly energy. The same kind of development pattern is also possible in the construction industry and in property investment.When someone is designing a low-carbon building in the future, there will not be enough space on the drawing board for all the existing approaches. Structural change in the low-carbon economy has caught the attention of both IPCC and the World Bank who have proposed various measures including a transition fund or some other kind of support for those industrial sectors where major pressures to conform will be brought by changes in the low-carbon economy. In the light of the research, timber construction appears to be an area that will benefit from the changes.

Nevertheless, change will not take place at the dictates of individual building materials, but will call for extensive cooperation across sales promotion boundaries. The Finnish construction industry is in a position to develop solutions in a spirit of broad-based consensus, where Finnish construction products and services are in pole position in the international race for low-carbon construction.

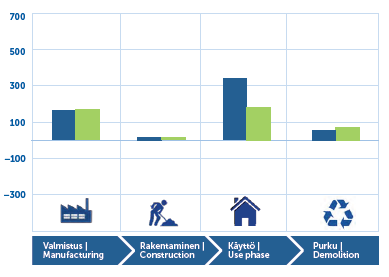

The carbon footprint of block of flat during the life-cycle

Traditionally, the carbon footprint of a building is made up largely of energy consumption during use (blue column). When we switch to the use of passive buildings, the carbon footprint is reduced and the proportion of emissions at the manufacturing stage increases (green column). Source: Dodoo A. et. al. (2013). Wälludden as a case study for three new wood building systems. In ‘Wood in Carbon Efficient Construction’ (ed. Kuittinen et. al., 2013).

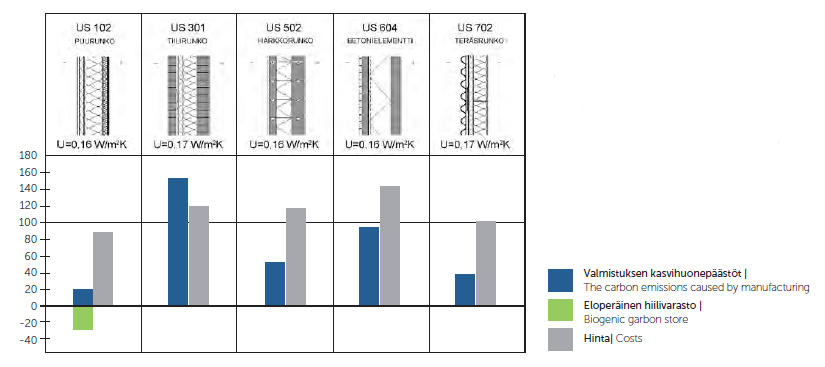

Comparison of the carbon footprint and building cost

Relationship between carbon footprint and building costs for wall construction. The carbon footprint is generated by adding together the emissions produced during the manufacture of the material. The costs consist of those for materials and those for work. The U-value of the constructions being compared are the same. Construction component costs are from 2013, emission calculations are the author’s.