Moisture properties of wood

Wood is a hygroscopic, meaning it is a material that absorbs water. Water gets into wood in three ways: as a fluid through the cell lumens through capillary tension, as vapour through the cell lumens, and as molecular diffusion through the cell walls. The moisture content of wood means the relationship between the mass of water in it and the mass of the timber without the water. (For example, if a piece of wood weighing 100 kg contains 50 kg of water, the moisture percentage is then 100%). The moisture content of newly sawn wood is usually 40-200%. In normal use the moisture content of wood varies between 8% and 25% by weight, depending on the relative humidity of the air.

The equilibrium moisture content of wood is a state corresponding to the air temperature and relative moisture, in which the moisture content of the wood remains steady. It should be noted about the equilibrium moisture content of wood that it is determined by the relative humidity of the air, not its absolute humidity. Relative air humidity is the ratio of the amount of water in the air to the maximum amount of water that the air could hold at the prevailing air temperature. Pre-dried timber reaches its equilibrium moisture content in a couple of weeks. The saturation point of wood grain means the ratio of moisture in the wood when the cell walls are saturated with water, but no free water appears in the cell lumina. As it dries, wood begins to contract, when its moisture content falls below saturation point. Correspondingly, as wood gets wet, expansion ends at the saturation point. In the main Finnish tree species, saturation point at +20 ºC is about 30%. Wood’s ability to absorb and release moisture (moisture capacity) can be used as a structural benefit, for example by using wood-based thermal insulation in construction, which balances the movement of moisture in the structures.

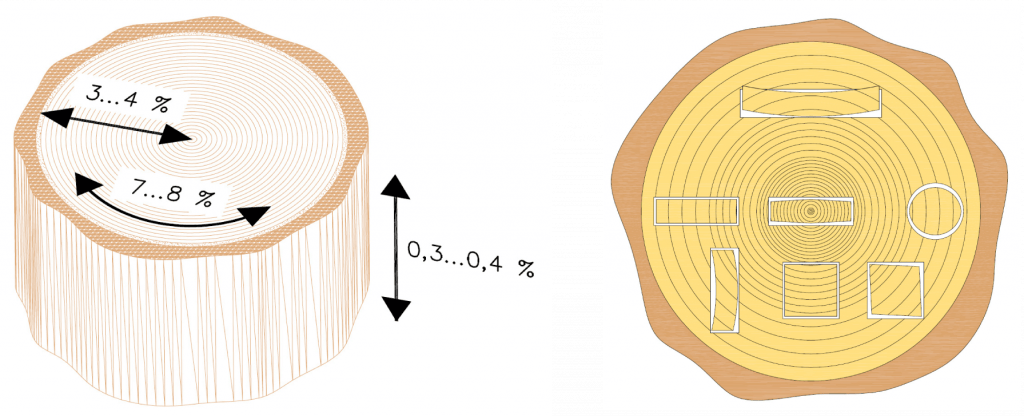

Wood contracts and expands in different ways in the radial and tangential directions of the growth rings and in the direction of the grain. This phenomenon goes by the name anisotropy. As it dries, wood shrinks from being completely wet to absolutely dry, in the tangential direction by an average of 8%, in the radial direction by about 4% and in the direction of the grain by only 0.2-0.4%. Heartwood is always drier than surface wood, which makes wood drying challenging. Anisotropy and the internal tensions of wood are also caused by the warping of the wood as it dries. The moisture dynamics of wood must always be taken into account in construction. The moisture dynamics may cause, for example, the frame of a building to sink in the middle. Furthermore, the great shrinkage of wood in the tangential direction causes large-sized timber to crack. Wood usually cracks in the place where the distance from the surface to the core is shortest.

As the density of wood increases, the shrinkage and expansion caused by moisture usually increase. As wood dries, its strength properties improve. For example, the compression and bending strength of wood increase by about two-fold as wood dries from fresh to 12-15%. The tensile strength of wood is at its greatest in the 6-12% moisture content range. As wood dries, its strength properties improve significantly when the moisture content falls below the saturation point of the grain. In the dimensioning of wooden structures, too, the moisture content of wood must be taken into account, because it affects the strength of the wood.

Wood begins to suffer damage if its moisture content remains at over 20% for long periods of time. The relative humidity of the surrounding air is then usually about 80-90% or more. Wood begins to go mouldy within a few months if the relative humidity of its surrounding air remains at more than 80% during this time. The 70% relative humidity of air can be considered as a critical value. When the relative humidity of the air exceeds 90%, wood begins to rot. A prerequisite for the moulding and decaying of wood, however, is for the temperature to be between +0 and + 40 ºC. Although in sub-zero temperatures the relative humidity of air may be more than 85% for long periods, wood does not suffer damage, because the temperature is insufficient for fungus and decay to develop. In order to thrive, fungal spores and rot fungus also need oxygen and nutrients, of which there are usually plenty both in the wood and in the surrounding air.

Fungus cannot penetrate deeper than the surface of the wood, so it is not harmful from a point of view of the strength of the wood. The spores spread by the fungus are, however, harmful to health, because they can give people different allergic reactions and mild symptoms of poisoning, such as a continually runny nose, dizziness and headaches. Because of this, the occurrence of mould must always be taken seriously. The weathering of wood is often mistakenly compared to it going mouldy. The weathering of wood is pigmentation caused by blue stain, which also reaches deeper into the structure of the wood. Blue stain spreads as spores or as mycelial growth and is particularly prevalent in CO2-storing conifers. Blue stain cannot develop at a temperature of less than +5 ºC. Weathering does not essentially affect the strength of wood.

The dependence of the moisture content of wood products on temperature and the relative humidity of the air

Example of the application (red dotted line)

- Source data:

- indoor air temperature + 22 ºC

- relative humidity of indoor air RH 50%

The table shows that the moisture content of wood is about 9.5% in the case based on the source data