Wood equalises indoor humidity

Fluctuations in indoor humidity over the course of the day can be reduced by using wood surfaces. Wood panelling allows indoor humidity to remain stable for a longer time and improves perceived air quality. This reduces the need for artificial ventilation and saves energy.

Daily, short-term fluctuations in indoor humidity come from the humidity caused by using the room. Longer stretches of rain and the change in seasons have longer-term effects. The absorption of moisture by wood-based interior decoration materials lowers the daily fluctuations in peak humidity values and improves the perceived quality of indoor air. In this case, there is less need for artificial ventilation and energy than when room surfaces are covered with a material that does not absorb water vapour.

Hygroscopic materials and moisture buffering

Hygroscopic materials absorbs and adsorbs humidity from surrounding environment to meet the equilibrium moisture with the environment. Wood is a hygroscopic material. It reacts to changes in humidity and to repeated moisture exposure both indoors and outdoors. This results in either an increase or a reduction in the moisture in the wood, which in turn stabilises fluctuations in humidity.

Hygroscopic materials dampen the peaks of relative humidity in indoor air through moisture buffering. This has a favourable effect on the perceived indoor air quality and thermal comfort. Thanks to its ability to buffer moisture, wood can play an active part in stabilising indoor air humidity. However, these capabilities are not yet being exploited on a large scale.

Studies have shown that untreated wood covering products can reduce the extreme values caused by variations in indoor air humidity up to 63 per cent, when compared to rooms with painted drywall. In addition, indoor air humidity remains optimal for a longer time. [1]

| MOISTURE BUFFERING refers to a material’s ability to dampen variations in the relative humidity in indoor air, which may be seasonal or daily. In practice, this means that the material absorbs and releases moisture. Moisture buffering plays a major role in understanding the risks posed by biological growth such as mould and the impact of indoor air on the health of occupants. It is important to take both health issues and moisture buffering capacity into account in hygrothermic calculations and in designing indoor climate systems. |

Wood’s ability to stabilise moisture

The tree species, the grain of the wood surface and the surface treatment all affect the moisture buffering capacity of wood. The moisture buffering capacity of wood is best when the surface is left untreated. Studies have shown that wood is superior to drywall in terms of moisture stabilisation. This lowers the peaks caused by humidity fluctuations and keeps the moisture at an optimum level for a longer time. [2] When wood is used to stabilise fluctuations in indoor humidity, the need for artificial ventilation is reduced, which saves energy.

In a comparison of identical houses where one interior was lined with solid wood, a second interior used drywall and a third interior used plywood veneer, the house with the solid wood had the lowest and most stable relative indoor humidity when compared to the other alternatives. The house with the drywall had the highest relative indoor humidity. The house with the plywood veneer had a lower relative indoor humidity than the one with drywall, but the fluctuations in temperature were the highest of all the options.

The study shows that spruce and pine indoor cladding lower the relative indoor humidity up to 50 per cent when compared to the painted drywall option. Perforated acoustic elements, which are surface-treated plywood veneer, also reduce fluctuations in humidity by 30 per cent. [1]

A second study investigated the effects of porous wood fibre board. This material lowered humidity spikes by up to 75-80 per cent. Due to the high moisture buffering capacity of wood fibre board, the optimal indoor humidity also lasted longer. However, porous wood fibre board is not often used as an interior design material as such – rather, it is typically coated in some manner. [2]

Species, wood grain and surface treatment

Different species of trees have different moisture buffering capacities. There can also be as much variation within a single species as between different species. This variation stems from different amounts of earlywood, latewood and soluble compounds, growth rates and porosity of wood. All these factors affect how the wood absorbs and releases humidity. [3]

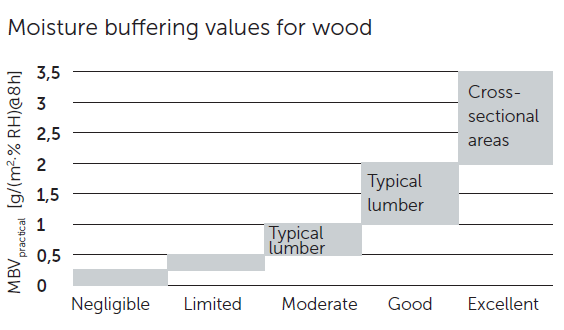

A method has been developed for classifying building materials by their practical moisture buffering capacity (MBVpractical) (NORDTEST method). The practical Moisture Buffer Value is determined in an experimental set up where the sample is exposed to cyclic step-changes in RH between high and low values for 8 and 16 hours respectively. The unit for MBVpractical is kg/(m²·% RH)

The MBVpractical values can be classified using five different categories. The Excellent category is more than 2. The Good category range between 1 and 2. Moderate range between 0.5 and 1, Limited range between 0.2 and 0.5, and Negligible range between 0 and 0.2. For example, the value of concrete is just below 0.4. Drywall gypsum and brick are 0.6 and 0.4, respectively. For untreated spruce and birch the values are roughly 1.0 and 0.8, respectively. [4]

Difference in moisture buffering capacity lies in the wood grain. Radial or tangential cuts are classed as moderate or good for all tree species, while the cross-sectional surface (a slab from the tree trunk) is in the excellent category. For example, the moisture buffering capacity of a cross-sectional area of pine is almost three times that of a surface sawn in a radial direction. [3] The figure shows the distribution of MBVs for typical lumber among the different categories.

Any surface coating will reduce the moisture buffering capacity of any indoor material. This means that the permeability of the coating has a critical impact on indoor air humidity. To take advantage of the moisture buffering capacity of the interior materials, the vapour resistance of the coating must be low. Studies have shown that the relative indoor humidity remains more stable where the surface coating is a vapour-permeable material and the wood can work properly when compared to surface coatings that are impermeable to water vapour. [2]

A varnish or latex paint coating can reduce wood’s moisture buffering capacity by up to 50 per cent. The effect of water-based acrylic paint is less severe. An increase in the pigment concentration in the coating generally increases its moisture permeability, which in turn increases the moisture transmission through the coating film. [1]

When selecting a suitable coating, take the wood’s moisture buffering capacity into account. Check the effects of the surface coating on vapour transmission. The vapour resistance is typically not indicated on the label, but must instead be requested from the manufacturer. The surface area of the moisture buffering material significantly affects moisture stability. Increasing the surface area reduces fluctuations in indoor humidity. When the surface area is small, the importance of the thermal insulation lining and moisture buffering capacity of the interior material increases. [2]

Accounting for various factors

The wood moisture buffering effect can be used when the surface class requirements for a fire class allow the use of wood. The surface area, surface treatment, and wood grain are the critical factors in wood that is operating as a humidity stabiliser. The species of tree also has an effect. The best results are achieved by using untreated wood as an interior material. If it is not possible to use untreated wood, one way to increase the moisture buffering is to allow air to circulate behind the interior structures to the untreated wood surface.

The moisture buffering surface area can also be increased by cutting grooves into the back of the interior structure. In this case, care must be taken to ensure that air can reach this surface. For example, the “Luukku” house at Aalto University, built in 2010, uses this approach.

All surface treatments reduce wood’s moisture buffering capacity, so attention must be paid to any coating’s vapour resistance. When a coating’s vapour permeability is low, increase the surface area of the wood and vice versa. When a coating’s vapour permeability is high, the surface area can be smaller.

Read also Breathable structures.

References and more information:

- Moisture buffering effects of interior linings made from wood or wood based products. Künzel H. M. et al. IBP Report HTB-04/2004/e. 2004.

- Improving indoor climate and comfort with wooden structures. Simonson C., Salonvaara M., Ojanen T. VTT Publications. 2001.

- The effect of wood anatomy and coatings on the moisture buffering performance of wooden surfaces. Vahtikari K., Noponen T. & Hughes M. WCTE 2016 World Conference Timber Engineering. 2016.

- Moisture buffering of building materials. Report. Rode C. et al. Technical University of Denmark. 2005.